Sub-nano resolution technology

Images in premium quality!

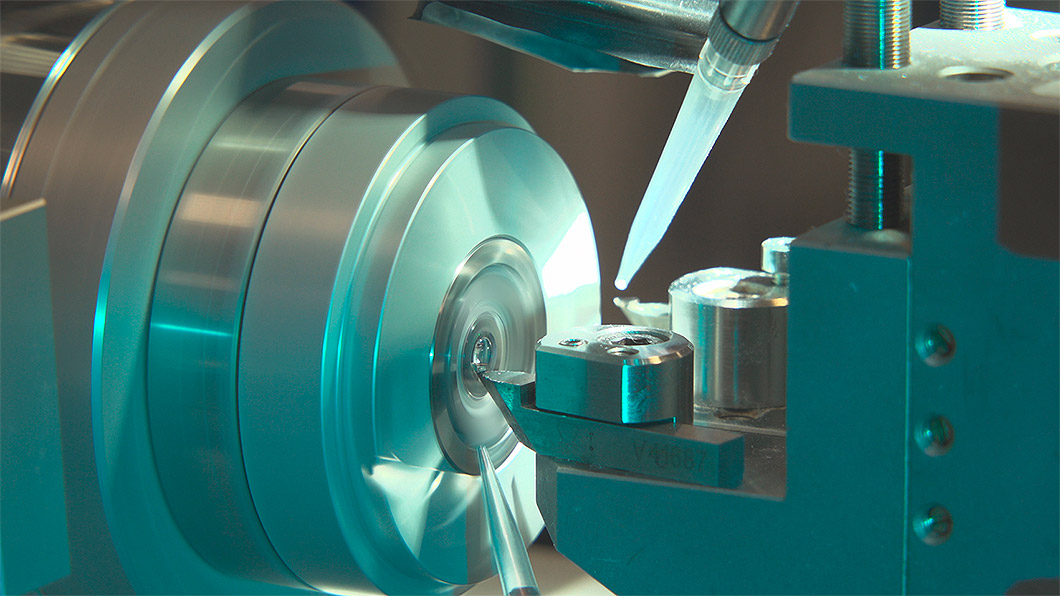

Sub-nano resolution technology delivers the highest precision and accuracy in the production of the extremely smooth optical surfaces of our premium IOLs. This is required to achieve high image quality for optimal patient vision. The roughness of the optical surface is in the single-digit nanometer range – that is, one millionth of a millimeter. SNR technology can only be achieved through the use of ultra-precision lathes. With this technology, we are a global leader.

Ultra-precision lathes:

maximum accuracy

Our lathes have an extremely high resolution of well below 1 nm. This means that the diamond tool can be positioned at intervals of <1 nm. The individual turning coordinates are precisely defined in the production programs. With the resolution of the lathe in the sub-nanometer range and the precise definition of the turning coordinates, the calculated curvature of the optics can be reproduced much more precisely than with conventional manufacturing processes.

Natural diamonds:

conical grinding for precise IOL surfaces

Not only the lathe and its individual components, but also the turning tools we use, ground natural diamonds, offer optimum conditions for outstanding processing quality. The lattice structure of the natural diamonds, for example, enables grinding with the lowest possible surface waviness and larger clearance angles. In contrast to the cylindrical shape of conventional tools, the diamonds we use are ground conically. The use of conical tools produces the highest quality aspherical lens shape and prevents systematic errors.

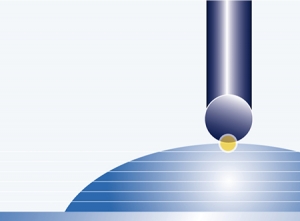

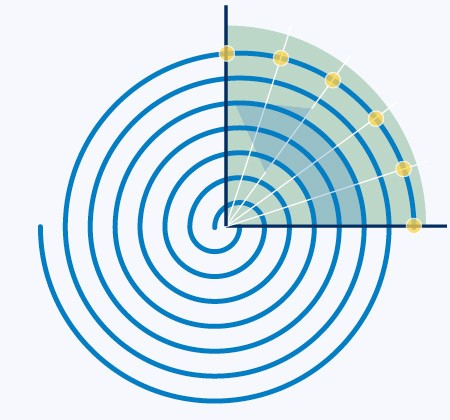

Schematic drawing:

Conical diamond cut for point-shaped processing

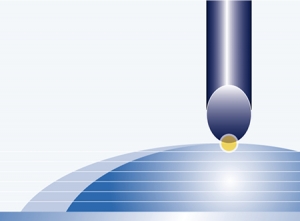

Schematic drawing:

Conventional, cylindrical diamond cut with resulting systematic error (light blue contour)

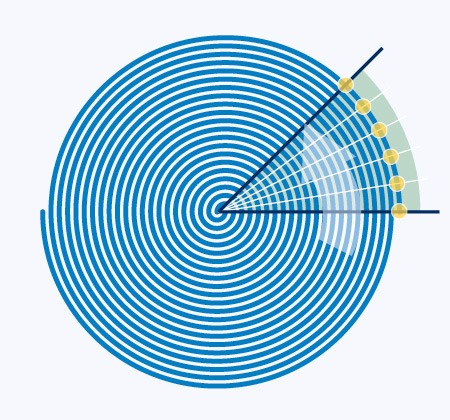

Decelerated processes for more quality

“Premium” is our priority and this is also reflected in our production processes: To offer our customers maximum quality, we allow sufficient time for production. A slower feed rate and the extremely high resolution of the lathe in the nanometer range enable smooth optic surfaces to be produced with a high degree of accuracy. Subsequent polishing of the IOL is not necessary.

Schematic drawing:

Slow rotation process with high resolution

Schematic drawing:

Fast rotation process and lower resolution

Your benefits with cutting-edge technology from HumanOptics

OUR

CUSTOMER SERVICE

YOUR

QUESTIONS

Our experts support you with your questions at any time.